News

Why Do Lithium-Ion Batteries Self-Discharge? Causes and How to Mitigate It

Self-discharge of lithium-ion batteries refers to the natural drop in charge/voltage when the battery is not connected to an external circuit (i.e., in an open circuit state) . This is an inherent characteristic of all batteries, albeit to varying degrees. While the self-discharge rate of lithium-ion batteries is relatively low, it still occurs. The main causes can be categorized as follows:

1. Inevitable chemical side reactions (normal self-discharge):

(1) Growth and dissolution of SEI film:

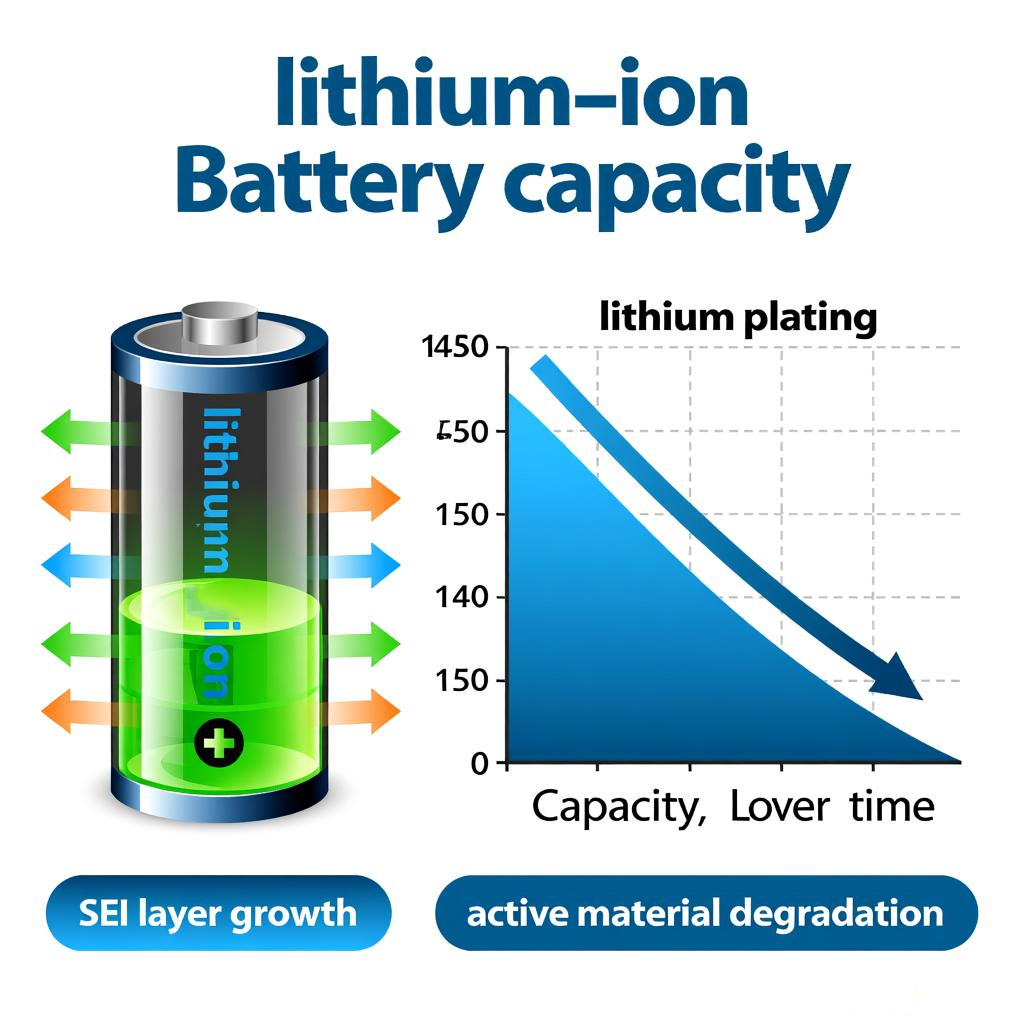

The surface of the anode (usually graphite) contains a solid electrolyte interface (SEI) film. This film forms during the initial charge and discharge and is crucial for the proper functioning of the battery. However, the SEI film is not completely stable. During storage, especially at elevated temperatures, the SEI film slowly dissolves and reforms. This reformation consumes lithium ions and electrolyte, leading to capacity loss and voltage drop. This is one of the primary causes of self-discharge in lithium-ion batteries.

(2) Oxidation/reduction of electrolyte:

Cathode materials (such as lithium cobalt oxide (LiCoO₂), lithium nickel cobalt manganese oxide (NCM), and lithium iron phosphate (LiFePO₄)) exhibit high oxidative activity in the charged state. Solvents (such as ethylene carbonate (EC) and dimethyl carbonate (DMC)) and additives in the electrolyte undergo slow oxidative decomposition reactions when exposed to the high potential of the cathode for extended periods. Similarly, on the anode side, despite the protection of the SEI film, trace amounts of reductive decomposition of the electrolyte may occur. These redox side reactions consume active lithium ions, leading to capacity loss.

(3) Impurity reactions in active materials : Trace impurities (such as metal ions Fe, Cu, Zn, etc.) present in the electrode active materials or current collectors may form tiny local short circuits between electrodes or participate in parasitic reactions, consuming charge.

2. Internal micro short circuit (caused by manufacturing defects or aging):

(1) Diaphragm defects: Tiny pinholes, impurities, or weak spots on the diaphragm may cause tiny electron conduction (micro-short circuit) between the positive and negative electrodes after charge and discharge cycles or long-term storage, directly causing charge leakage. This is the main cause of abnormally high self-discharge. In addition, although the diaphragm prevents electron conduction at a macro level and only allows ions to pass through, at a micro level, the electrode material itself or the conductive agent network may form an extremely weak electron leakage path through the electrolyte.

(2) Dendrite penetration: In batteries that are overcharged, charged at low temperatures, or severely aged, lithium metal may deposit unevenly on the surface of the negative electrode, forming dendrites. Sharp dendrites may penetrate the separator, connecting the positive and negative electrodes, and causing an internal short circuit.

(3) Metal dust during the manufacturing process: If metal dust introduced during the production process (such as that generated when cutting electrodes) remains between the electrodes or the diaphragm, it may also cause micro short circuits. Absolute dust-free production is impossible. When the dust is not enough to pierce the diaphragm and cause a short circuit between the positive and negative electrodes, its impact on the battery is not significant; however, when the dust is serious enough to pierce the diaphragm, the impact on the battery will be very significant.

3. Temperature effect:

Temperature is one of the most critical factors. Higher temperatures significantly accelerate the rates of all chemical reactions that lead to self-discharge (SEI film evolution, electrolyte decomposition, impurity reactions, etc.), leading to a sharp increase in the self-discharge rate. Therefore, long-term battery storage should be carried out at low temperatures (but avoid freezing).

4. Impact of self-discharge:

Capacity loss: The most direct impact is the reduction of available battery capacity.

Voltage drop: The open circuit voltage decreases with storage time.

Accelerated aging: Side reactions during self-discharge (such as continued SEI growth) consume active lithium and electrolyte, which is itself an aging mechanism.

Difficulty in estimating state of charge: Self-discharge makes it difficult to accurately determine the remaining charge based on voltage alone.

Safety risks (extreme cases): Abnormally high self-discharge (such as severe internal micro-short circuit) may cause the battery temperature to rise and even trigger thermal runaway.

The main countermeasures for battery self-discharge are as follows:

(1) Optimize battery design and materials: improve the stability of the SEI membrane, develop electrolytes with stronger oxidation resistance and high-purity materials, and improve the quality of the diaphragm.

(2) Control storage conditions:

Temperature: The most important thing! Try to store the battery at low temperatures (e.g. 10°C-25°C, avoid temperatures below 0°C).

State of Charge: When storing the battery for a long time, charge it to a moderate state of charge (e.g., 40%-60%). A fully charged state will accelerate oxidation of the electrolyte by the positive electrode, while a completely depleted state may cause over-discharge damage to the negative electrode.

(3) Regular recharging: For batteries that have been idle for a long time, the voltage/SOC should be checked regularly, and appropriate charging (such as charging to 50%) should be performed when the power is too low to avoid deep discharge and damage to the battery.

(4) Strict control of the manufacturing process: reduce impurities and metal dust to ensure the quality of the diaphragm.

Lithium-ion battery self-discharge is primarily caused by inherent chemical side reactions, such as the instability of the negative electrode SEI film and the slow oxidation/reduction decomposition of the electrolyte on the electrode surface (especially the positive electrode) . Internal micro-shorts caused by manufacturing defects (such as separator defects and impurities) can lead to abnormally high self-discharge rates . Temperature is the largest external factor affecting self-discharge rates . Understanding the causes of self-discharge can help optimize battery usage and storage strategies, extending battery life.